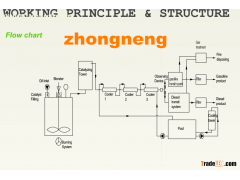

Pump the waste oil into the negative pressure thermal cracking pyrolysis furnace, heat it and distillate into oil vapour, the oil vapour pass through the gas manifold, then go throught three-stage condenser to cool down the hot vapor to petrol and diesel oil; the waste gas will be collected and transport to the burner as fuel; and the

residue will be discharged automatically by spiral.

Stop heating when reaction of waste oil is completed, in the distillation kettle, remove all the remaining residues, then all system can be reused for next time.

Main structure:

The DOD Series machine is composed of following systems:

A. Pre-treatment System: pre-treat the waste oil, remove particles and water content.

B. Catalyst system: Catalyst Reactor, blender;

C. Distilling system: distilling tower, distilling kettle, heater unit, circle pump;

D. Cooling system: refrigerating machine, water pump, water tank, cooler, Condenser;

E. Degasification system: Depends on actual need.

F. Vacuum System: depends on actual need.

G. Transit oil storage system: distilling oil storage tank

H. Controlling system: all kinds of gauge (vacuum gauge, pressure gauge etc.), temperature controlling system and electrical controlling system.

I. Exhaust gas processing system

J. Filtering System: connect our TYA series or JL Series to remove more impurities from the oil, make the oil cleaner.

contact

Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

Email: sales@zhongnengcq.cn

Tel: +86 023 68090921

Fax: +86 023 68060921

Website: www.zhongnengcq.cn / www.zhongnengcq.com

Multi function diesel oil distillation system